In the manufacturing of commercial appliances, precision and efficiency are critical to producing high-quality products. A Panel Bender is an essential piece of equipment in this process, specifically designed for bending sheet metal panels used in the production of commercial appliances such as refrigerators, ovens, dishwashers, and more.In the manufacturing of commercial appliances, precision and efficiency are critical to producing high-quality products. A Panel Bender is an essential piece of equipment in this process, specifically designed for bending sheet metal panels used in the production of commercial appliances such as refrigerators, ovens, dishwashers, and more.

A panel bender is a machine used in the manufacturing industry for bending and forming sheet metal panels. These machines play a crucial role in shaping metal components with precision, speed, and consistency. They are utilized in various industries, including the production of commercial appliances.

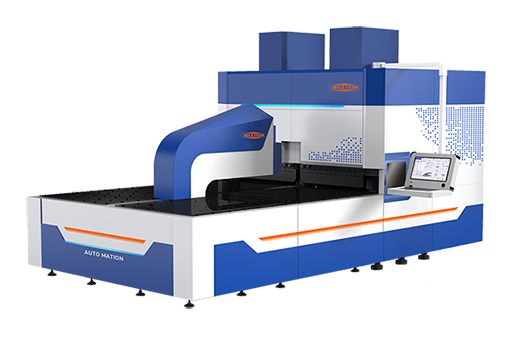

For the production of commercial appliances, such as refrigerators, ovens, or other metal-based devices, a panel bender like Hisman's may offer advanced features tailored to the specific requirements of appliance manufacturing. These machines are designed to efficiently bend and shape metal sheets to create the intricate and customized components needed for assembling commercial appliances.

With advanced automation and high-speed capabilities, the Panel Bender ensures consistent, precise bends without compromising on the integrity of the material. It allows manufacturers to achieve complex shapes with minimal manual intervention, reducing production time and costs. The machine’s flexibility also enables it to handle a variety of panel sizes and materials, making it a versatile solution in modern manufacturing environments.

By incorporating Panel Benders into their production lines, commercial appliance manufacturers can enhance productivity, maintain product quality, and meet the growing demand for durable, well-engineered appliances.

With advanced automation and high-speed capabilities, the Panel Bender ensures consistent, precise bends without compromising on the integrity of the material. It allows manufacturers to achieve complex shapes with minimal manual intervention, reducing production time and costs. The machine’s flexibility also enables it to handle a variety of panel sizes and materials, making it a versatile solution in modern manufacturing environments.

By incorporating Panel Benders into their production lines, commercial appliance manufacturers can enhance productivity, maintain product quality, and meet the growing demand for durable, well-engineered appliances.