Office furniture panel bending with a panel bender involves using specialized machinery to shape panels for desks, partitions, and cabinets. This process ensures precise bends and curves, creating sleek and functional office furniture designs with efficiency and accuracy.

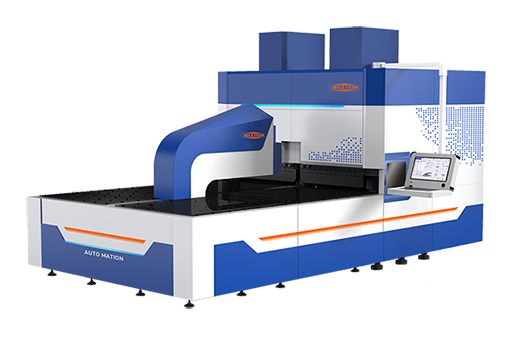

In the production of modern office furniture, precision and efficiency are key to delivering high-quality, durable pieces. A Panel Bender is a vital machine in this process, specifically designed for bending sheet metal panels used in office furniture components like cabinets, desks, partitions, and shelving units.

This advanced bending technology ensures that the metal panels used in furniture manufacturing are bent with exact precision, creating clean lines and smooth edges that are essential for both aesthetics and functionality. Panel Benders allow for the bending of various materials, including steel and aluminum, which are commonly used in office furniture due to their strength and durability.

With automation and high-speed capabilities, panel bending machines streamline the production process, reducing labor costs and increasing output while maintaining consistent product quality. By integrating a Panel Bender into their operations, office furniture manufacturers can enhance their productivity and create sophisticated, long-lasting furniture designs that meet the demands of modern workspaces.